A foremost expert’s views on Phytosanitary Irradiation

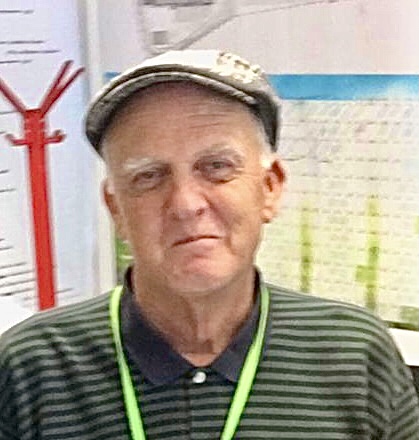

Guy Hallman is an entomologist and one of the pioneers of PI. In 1994 Guy was tasked by the USDA to examine the confusing science and recommend treatment doses when the US began using the technology against fruit flies in Hawaii on a continuing basis starting the next year. His analyses and research were the basis for many treatments used in countries adopting the new technology. The FAO/IAEA used him to advise countries and international plant protection organizations in PI and develop guidelines for the new technology. Guy was part of the team that developed the International Standard on Phytosanitary Measures # 18 (ISPM 18) on phytosanitary irradiation twenty years ago and he is involved in the current revision. After retiring from the USDA in 2014, Guy spent 3 years researching phytosanitary treatments with the FAO/IAEA in Seibersdorf, Austria. He remains an active consultant with the FAO/IAEA, USDA, and IPPC

PSiP: PI has been and is still making progress. How to stimulate further and faster growth?

GH: The volumes of product commercially irradiated for phytosanitary purpose have been increasing by approximately 10% per year, but the global yearly volume of about 50,000 tons is still minor compared to cold, heat and fumigation treatments. To stimulate progress, industry should target replacing other treatments that have less advantages than PI and make this known to marketers and consumers. For example, promote faster irradiation instead of slow, lengthy (14-22 day) cold treatments to get product to market faster and take advantage of better prices early in the season.

Another example: almost all of the 95 million boxes of mangoes imported into the US each year are immersed in 46˚C water for 65-110 minutes. PI provides a safer mango of superior eating quality compared with hot water immersion. The US imports 95% of all products irradiated for quarantine, so targeting the US market makes economic sense in the short term. The hot water treatment for mangoes has the dubious distinction of being the only phytosanitary treatment that has caused microbial food poisoning among consumers, yet it is considered “organic” while irradiated product are not yet accepted as “organic”. As mangoes are heated in water they expand, pulling in a little water through the stem end. If the water is not adequately sanitized, pathogens may be absorbed with the water.

Organic is an approach supposedly precautionary that aims to use “tried and true” safe technology. As irradiation becomes more common, I predict that some in the organic industry will accept it, as it is the treatment that least affects commodity quality, which is a key objective of organic growing.

In the longer term, more countries need to be convinced to use PI; only about a dozen countries are currently involved in either export and import. Major markets in Europe and Asia are not yet participating.

PsIP: Isn’t the small number of irradiation facilities where fresh produce can be irradiated for phytosanitary purpose a major obstacle?

GH: For sure. That limited number keeps costs higher than they should be and makes logistics difficult. For example, the US which is the major importer of irradiated produce, allows irradiation upon arrival at some ports. That allows importers to test markets and work out marketing strategies and costs without the high cost of investing in irradiation facilities. However, there are only a couple of facilities in the US doing this treatment upon arrival, so locations of these facilities are not optimal, costs are not competitive and potential markets are, thus, restricted.

PsIP: Will Methyl Bromide remain as widely used as it is for much longer?

Considerable MB is still used for phytosanitary purposes especially in the US for imported grapes, blueberries, citrus, cut flowers, asparagus and leafy vegetables. Its use will probably continue in the foreseeable future. Irradiation could replace much of these uses now, but as I mentioned before, logistics and scarcity of facilities leading to increased costs limit that possibility. One unfair edge that MB has over PI is that fumigation does not have to be mentioned on labels, contrary to irradiation. If fumigation had to be mentioned, I suspect that the use of MB would decline significantly.

PsIP: Isn’t there more interest in Australia than in the US now?

Australia is making significant progress. The US was the first commercial user of PI, on isolated occasions in 1986 and 1987, and on a continual basis beginning in 1995. The US made many of the initial progressive decisions about its use and remains by far the major importer of irradiated produce from 11 countries. But the US has not made progress exporting. Only a couple shipments of irradiated peaches were exported to Mexico.

It wasn’t until late 2004 that Australia made the first commercial shipment using PI, which was mangoes to New Zealand. Today Australia is a center of diversity and progress for PI. For example, Australia exports irradiated fruits to 5 countries and imports from a few. Of note are the recent decisions by Australia to permit PI for all types of fresh fruits and vegetables, the construction of a new X-ray PI facility, and the acceptance of a generic dose for mites of 500 Gy.

PsIP: What should the directions of PI research be?

GH: A new 5-year Coordinated Research Project by the FAO/IAEA developed a few months ago addresses research directions for PI. The directions we decided upon include developing additional generic doses for groups of quarantine pests, such as mealybugs, mites, scale insects, leaf miners, thrips and pupae of Lepidoptera, lowering the generic dose for all insects except pupal and adult Lepidoptera from the current 400 to 300 Gy and examining factors that may affect the efficacy of irradiation. The results of this research should bring down doses for many key pests from the current 400 Gy to 250 Gy or less.

PsIP: Do we need a test to detect irradiated insects?

I do not think so. I do not think that the absence of a test is an obstacle to more countries accepting the technology. Furthermore, if it is suggested that we need reliable tests that can determine within a reasonable margin of error what dose was absorbed by live insects found in irradiated produce, it gives reluctant countries an excuse to delay the acceptance of PI until those tests become available, which may be never. What is needed is confidence in the process, as is achieved by countries participating in PI presently and is based on accurate dosimetry, good treatment practices and adequate record keeping.

However, I do understand the concern. As PI generally does not result in acute pest mortality it is a significant leap of faith for plant protection organizations to accept that there is negligible risk of pest introduction when live insects are found upon inspection. With all other phytosanitary treatments, live insects upon post-treatment inspection indicate failure of treatment and cause for rejection of the commodity lot. And this has happened for all of the major treatment categories based on heat, cold and fumigation. But the difference between these treatments and PI is the tighter process control around PI; other treatments would do well to adopt this level of control.